This article on Inverted Bucket Steam Trap provides information on various aspects of these steam traps such as operation method, design variations, various features, typical installation in piping system and applications.

Inverted bucket steam trap is a density operated steam trap which operates on the difference in density between steam and water.

Working of a Inverted Bucket Steam Trap

In this trap, an inverted bucket floats in the condensate that has filled the strap.

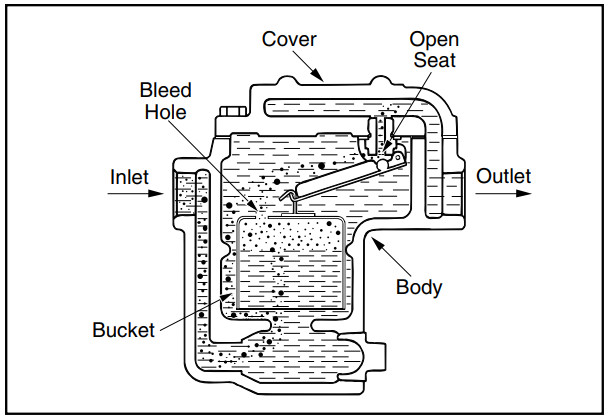

Startup / Only Condensate / Open Position

- Inverted bucket steam trap must be filled with water i.e. primed at initial start-up to make it work properly.

- Also in low load or superheat conditions, the trap may also need to be primed.

- During start-up, air is vented through a bleed hole in the top of the bucket into the return line.

- When air or steam flows into the trap, it enters the underside of the bucket and collects in the top of the bucket.

- Under normal working condition, trap is always filled with condensate. It it fails, it will have no condensate.

[google-square-ad]

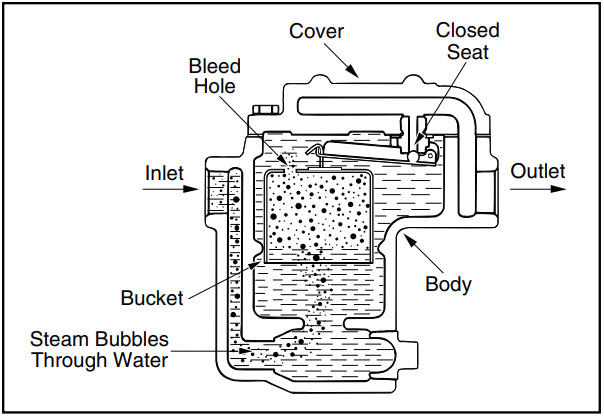

Steam or air / Closed Position

- When steam enters the trap, it first goes inside the bucket due to which bucket becomes buoyant and rises.

- This upward motion of bucket causes the lever mechanism attached to top of bucket to close the valve, thereby stopping flow of steam.

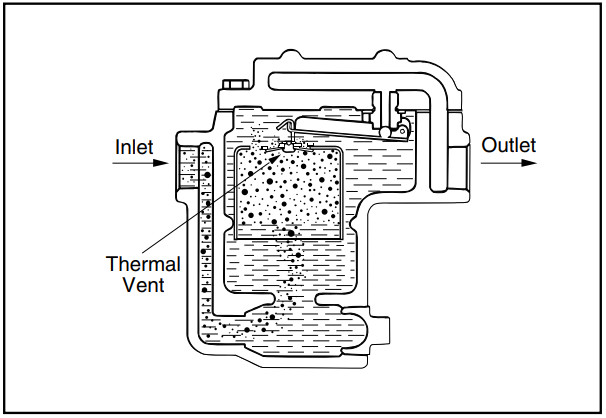

Open Again on Steam Condensation

- The bucket loses its buoyancy as the enclosed steam condenses due to radiation losses and steam escaping through the bucket vent hole.

- When this happens, the weight of the bucket will cause it to fall and pull the valve off its seat, and the cycle repeats.

Optional Thermal Vent

An optional thermal vent installed in the bucket allows faster air venting during start-up.

[google-square-ad]

Features of Inverted Bucket Steam Trap

- Inverted buck steam traps have limited capacity as far as venting of cold air during start up is concerned.

- It is important to maintain water seal in inverted bucket steam traps.

- Loss of water seal will defeat the functioning of the inverted bucket steam trap.

- All inverted bucket steam traps incur some amount of steam loss (bubbling through the vent hole).

- The condensate discharge is not continuous from inverted bucket steam traps. Hence they have reduced heat transfer efficiency.

- Inverted bucket steam traps are suitable for operating at fairly high pressures.

- Inverted bucket steam traps have a fairly high resistance to water hammer since the condensate / steam is lead to a reasonably large volume of the bucket.

- Inverted bucket steam traps must be protected from freezing under subzero ambient conditions.

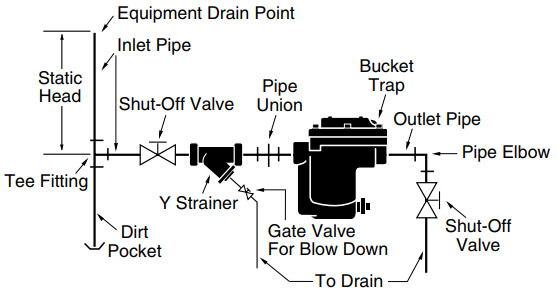

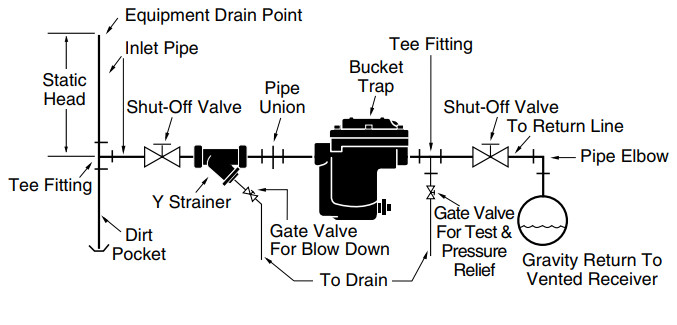

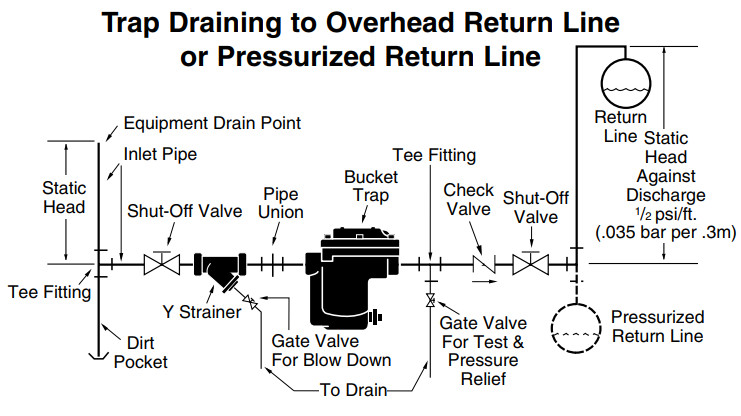

Typical Installation Piping

Trap draining to open drain

Trap draining to gravity return line

Trap Draining to Overhead Return Line

or Pressurized Return Line

Applications of inverted bucket steam trap

Inverted bucket steam traps are best for stable, steady load and pressure conditions. They can be used at following equipments.

- As process main drip traps for continuous operations.

- In steam lines where condensate is lifted or drains into wet return line.

- For heat exchangers without a modulating steam regulator.

- In high pressure applications.

- For drum type roller dryers.

- For steam separators.

- They can be also used for Laundry equipment.

- They have a use in siphon or tilting kettles.