Blinds, Spaces and Spectacle Blinds are used for the purpose of positive shut off of a piping system where mere shut off using valves is not sufficient as valves are prone to leakage. These are generally used in hazardous services like hydrocarbon fluids.

Tags : #Piping_Engineering #Piping_Fittings #Blinds #Spacers #Spectacle_Blinds

Single line blind or blank is installed adjacent to a valve to ensure positive shut-off. Their purpose is to prevent accidental flow through a pipeline to a vessel.

With the exception of cast iron, plastic, or fiberglass services, they are not drilled with bolt holes, but fit inside the bolt circle of mating flanges.

Normally upto 16″, spactacle blinds are used. For 18″ and above, spacer and blanks are used. Thickness of spectacle blind is specified based on the pressure and pipe size.

Mixed Material Joints

ASME B16.48 specifies that should either the two flanges or the line blank in a flanged line blank assembly not have the same pressure-temperature rating, the rating of the assembled joint at any temperature shall be the lower of the flange or line blank rating at that temperature.

Handle

The handle or web (tie bar) may be integral or attached to the line blank or spacer. The web and its attachment shall be capable of supporting the weight of the blank or spacer in all orientations without permanent deformation to the web.

Applicable Dimensional Standards

ASME B16.48 : Line blanks.

- This standard specifies dimensions of spectacle blinds.

- In this standard Spectacle blinds are available only up to 24″.

- For 2500# spectacle blinds are upto 12″.

- No 400# spectacle blinds in this standard.

- Facings available are Raised Face, Female Ring Joint and Male ring joint.

[google-square-ad]

Materials of Construction

As they are normally manufactured from plates, piping materials for plates are used :

- SA 240 : Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

- SA 203 : Standard Specification for Pressure Vessel Plates, Alloy Steel, Nickel.

- SA 516 : Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service.

- SA 285 Standard Specification for Pressure Vessel Plates, Carbon Steel, Low- and Intermediate-Tensile Strength.

- SA 387 Standard Specification for Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum.

Spectacle Blind / Figure-8 Blank

These have both blank and spacer as a single component in the shape of 8. ASME B16.48 specifies dimensions for figure-8 blanks.Spectacle blinds are not manufactured in large size due to weight issues.

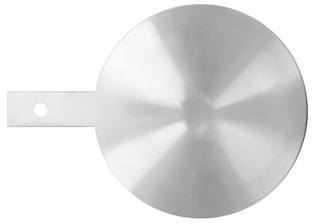

Paddle Blanks

When spectacle blinds become too heavy, pair of paddle blank and paddle spacer is used instead. A paddle blank is similar to the solid end of a figure-8 blank. It has a plain radial handle. It is generally used in conjunction with a paddle spacer in large sizes.

[google-square-ad]

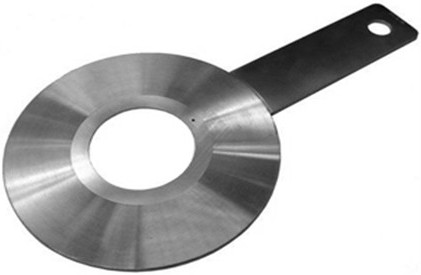

Paddle Spacer

Paddle spacer is used at the place of paddle blind when line is to be put into service. It serves to fill the gap between flanges due to paddle blank. Ring spacer replaces single blind, with same thickness as blind. Thick single blinds or rigid piping systems normally require ring spacers.

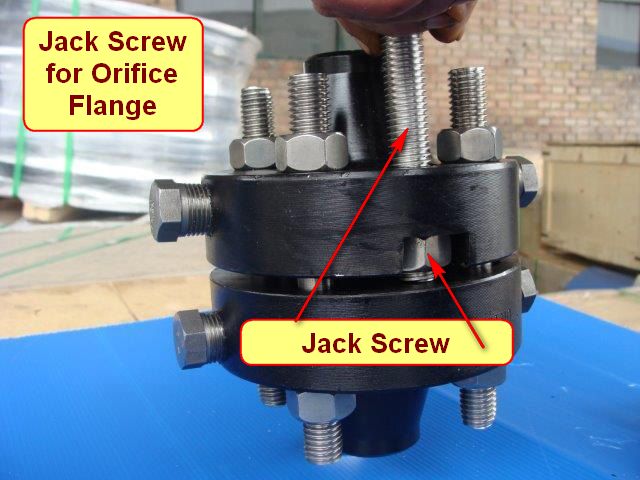

Jack Screw Flanges

Jack Screw Flange is required for larger size blinds. Jack screw help in spreading the flanges and replacing the spacer/blind or turning of spectacle blind.

Following image shows jackscrew in an orifice flange assembly. Same type of jack screws are also used for large size blinds.

Piping Material Specification

In PMS Specify NPD, Pressure Class, MOC, Dim Std and facing type.

Layout Considerations

- Flanges shall be staggered with grouped.

- Spectacle blinds shall be accessible from grade, platform or if below 4500 mm by a portable ladder, or temporary scafolding.

- Blinds in pipeway, regardless of pipeway height, are considered accessible.