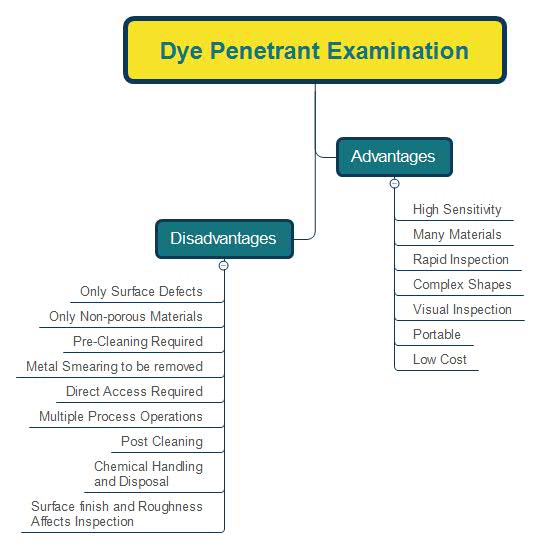

Dye penetration inspection has it own advantages and disadvantages compared to other non-destructive testing methods.

[google-square-ad]

ADVANTAGES

- Inspection with this method is of low cost (materials and associated equipment are relatively inexpensive)

- It is possible to do rapid inspection of large areas and volumes.

- It has high sensitivity (small discontinuities can be detected).

- This method is suitable for parts with complex shapes.

- Equipment is highly portable (materials are available in aerosol spray cans).

- Various types of materials can be inspected such as metallic and nonmetallic, magnetic and nonmagnetic, and conductive and non-conductive materials may be inspected.

- Indications are produced directly on the surface of the part and constitute a visual representation of the flaw.

DISADVANTAGES

- With this method, only surface breaking defects can be detected.

- It is possible to inspect only materials with relatively nonporous surface.

- It is necessary to pre-clean the material since contaminants can mask defects.

- Metal smearing from machining, grinding, and grit or vapor blasting must be removed.

- Direct access to the surface being inspected is necessary.

- Surface finish and roughness can affect inspection sensitivity.

- It is necessary to perform and control multiple process operations.

- Post cleaning of acceptable parts or materials is required.

- This method involves chemical handling and its proper disposal.

[google-square-ad]

Related Posts

|  | |

| This is one of the oldest and very simple NDT examination. It is also known …Read More.. | ||

|  | |

| Liquid penetrant inspection is used to detect any surface-connected discontinuities such as cracks from fatigue, …Read More.. | ||