This article on Ball Float Steam Trap provides information on various aspects of these steam traps such as design variations, effects of water hammer, method of operation, advantages, disadvantages, materials of construction, typical dimensions etc.

Ball float steam trap is a kind of mechanical steam trap which rely on on the difference in density between steam and condensate in order to operate. These steam traps can continuously pass large volumes of condensate and are suitable for a wide range of process applications. The ball float type trap operates by sensing the difference in density between steam and condensate.

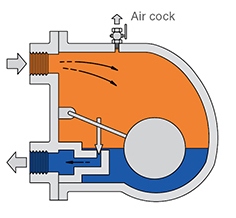

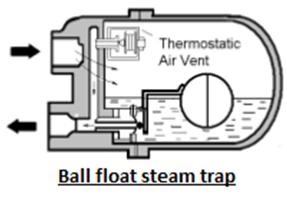

Ball Float Steam Trap with Air Cock

This is simpler and older version of ball float steam trap in which condensate reaching the trap will cause the ball float to rise, lifting the valve off its seat and releasing condensate. This valve is always flooded and neither steam nor air will pass through it, so early traps of this kind were vented using a manually operated cock at the top of the body.

[google-square-ad]

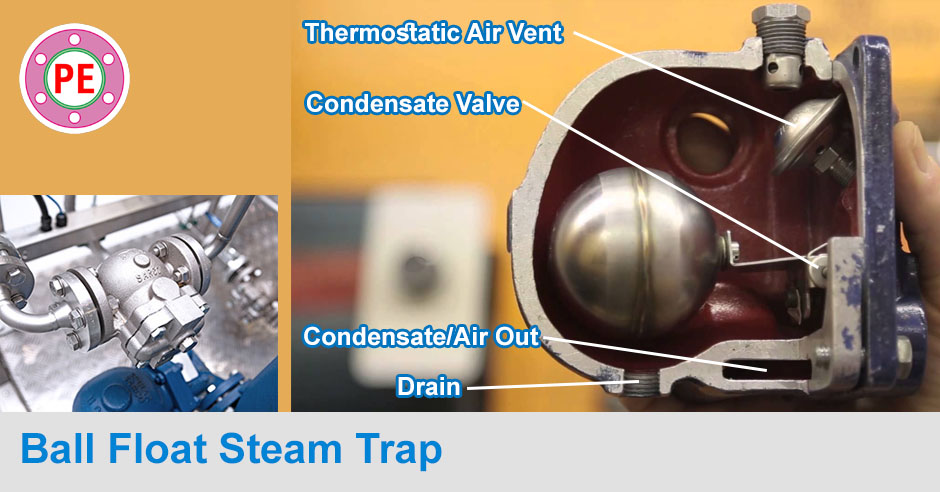

Ball float steam trap with thermostatic air vent

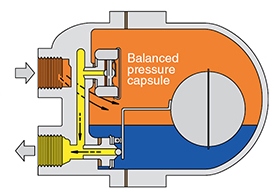

Modern traps use a thermostatic air vent. These are ball float trap with thermostatic air vent. This allows the initial air to pass whilst the trap is also handling condensate.

The automatic air vent uses the same balanced pressure capsule element as a thermostatic steam trap, and is located in the steam space above the condensate level. After releasing the initial air, it remains closed until air or other non-condensable gases accumulate during normal running and cause it to open by reducing the temperature of the air/steam mixture. The thermostatic air vent offers the added benefit of significantly increasing condensate capacity on cold start-up.

[google-square-ad]

Effects of Water Hammer

In the past, the thermostatic air vent was a point of weakness if water hammer was present in the system. Even the ball could be damaged if the water hammer was severe. However, in modern float traps the air vent is a compact, very robust, all stainless steel capsule, and the modern welding techniques used on the ball makes the complete float-thermostatic steam trap very robust and reliable in water hammer situations.

Advantages of Ball Float Steam Trap

- In many ways the float-thermostatic trap is the closest to an ideal steam trap. It will discharge condensate as soon as it is formed, regardless of changes in steam pressure.

- The trap continuously discharges condensate at steam temperature. This makes it the first choice for applications where the rate of Heat Transfer is high for the area of heating surface available.

- It is able to handle heavy or light condensate loads equally well and is not affected by wide and sudden fluctuations of pressure or flowrate.

- As long as an automatic air vent is fitted, the trap is able to discharge air freely.

- It has a large capacity for its size.

- The versions which have a steam lock release Valve are the only type of trap entirely suitable for use where steam locking can occur.

- is resistant to water hammer.

[google-square-ad]

Disadvantages of Ball Float Steam Trap

- Although less susceptible than the inverted bucket trap, the float type trap can be damaged by severe freezing and the body should be well lagged, and / or complemented with a small supplementary thermostatic drain trap, if it is to be fitted in an exposed position.

- As with all mechanical type traps, different internals are required to allow operation over varying pressure ranges. Traps designed to operate on higher differential pressures have smaller orifices to balance the bouyancy of the float. If a trap is subjected to a higher differential pressure than intended, it will close and not pass condensate.

[google-square-ad]

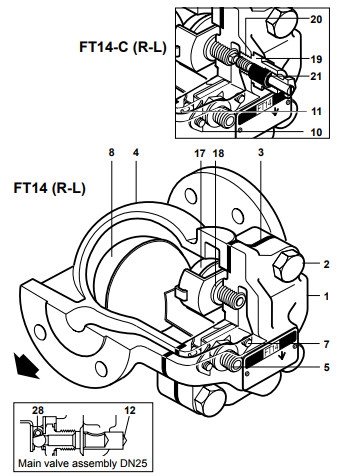

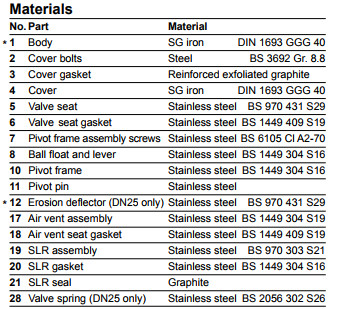

Materials of Construction

Ball float steam traps are mostly made of of following materials .

- Body : SG Iron

- Internals : Stainless Steel

Here is a sample parts details with materials of construction for Spirax Sarco Ball Float Steam Trap FT14.

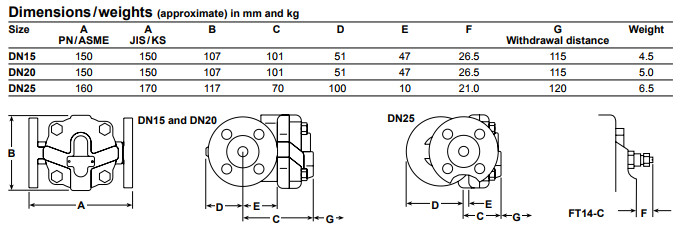

Typical Dimensions for Ball Float Steam Traps