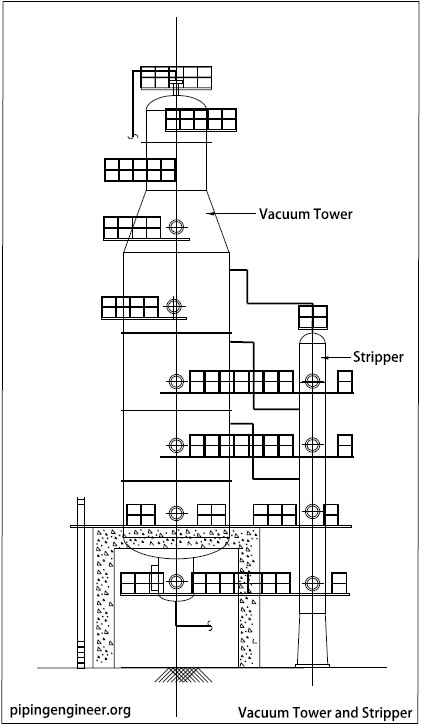

Towers are named for the service or type of unit they are associated with. For example, a stripper is used to strip lighter material from the bottoms of a main tower or a vacuum tower.

It is generally used in vacuum/crude oil unit for distilling crude bottoms residue under vacuum pressure. Following drawing shows a typical vacuum tower and stripper.

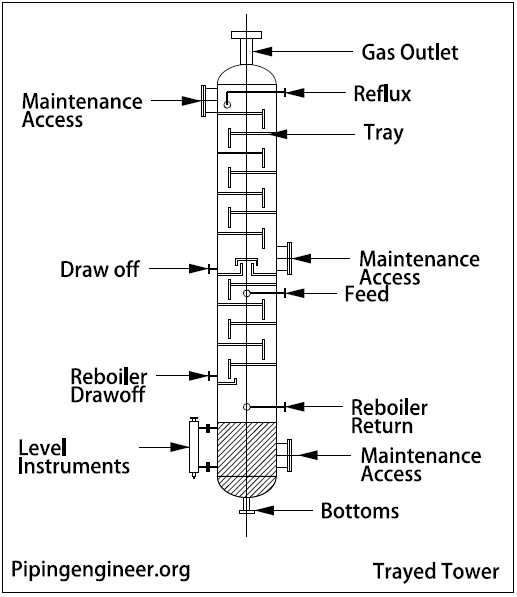

From the outside, tower configurations are similar in appearance, varying only in dimensions; some towers have swaged top and bottom sections. The principal difference among tower is the type and layout of the internal components that control the vapor-liquid contact.

Following figure shows a typical trayed tower with some of its associated components.

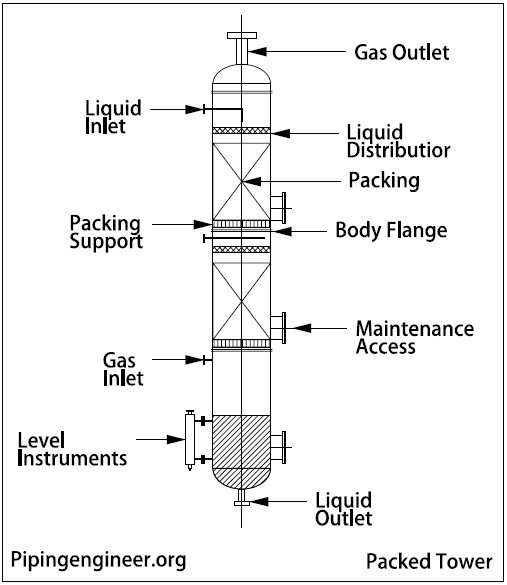

In a packed tower, instead of having trays, the units are packed with beds of metal rings. On entering the tower, the liquid passes through a distributor that routes the liquid evenly down through the packed beds of metal rings.

Rising vapors passing through the beds come into contact with the descending liquid. In a manner similar to trayed tower operation, the liquid is partially vaporised by the heat from the vapors and the vapors are condensed by the cooler liquid.

Following drawing shows a typical gas-liquid packed tower and its principal components.