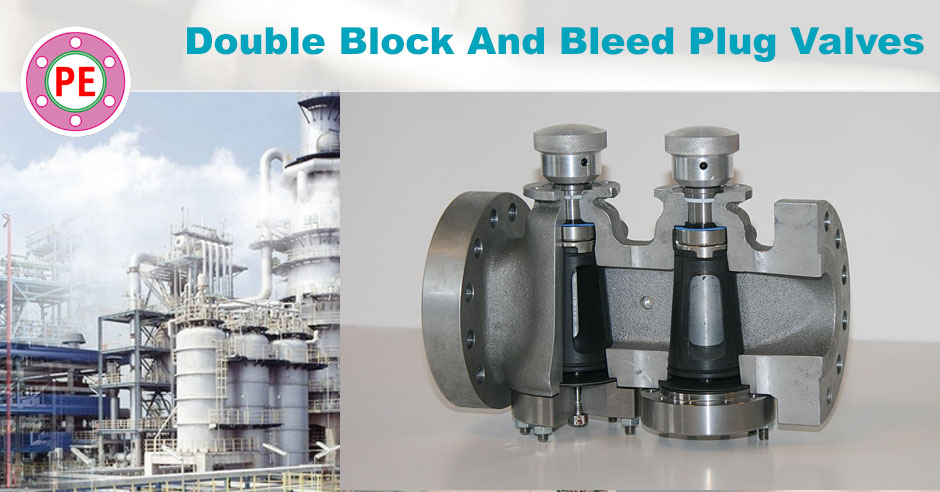

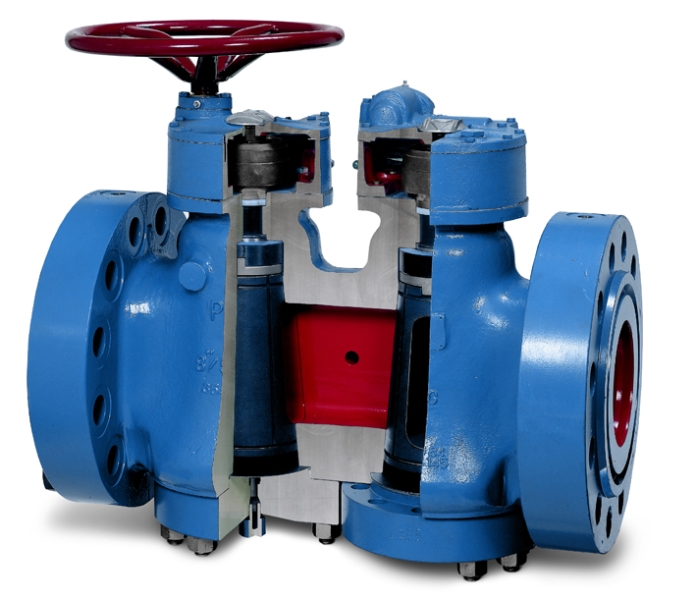

Double block and bleed plug valve (also known as double isolation plug valve) has two plug valves in one with small drain in the middle. It is designed for critical shutoff applications where absolute shutoff is required for safety, environmental or process reasons. These valve are lubricated plug valves.

Applications

Double block and bleed plug valves are used for critical applications like :

- Compressor isolation

- Pump isolation

- Meter isolation

- Water or gas injection system isolation

- Critical vents, drains and blow-downs to atmosphere

[google-square-ad]

Benefits of Double Block and Bleed Plug Valve

- As these are two valves in one, Installation and maintenance costs are reduced dramatically.

- Normally uses dynamic balance pressure balance and sealing technology.

- Each valve are made according to standard ANSI

Valve dimension of a single valve. - As there are two seats, it means two times the safety.

- They have maximum port area for better flow.

Availability

Flowserve company makes these valves in 2”-24” ANSI #150, 300, 600, 900, 1500, 2500 API 6A 2000, 3000, 5000 with following features.

- Ground and Lapped Metal-to-Metal Seats Ensure Tight Shutoff to Resist Erosion

- Seats are Fully Protected with Valve Open.

- Dynamic Balancing Prevents Unequal Pressure Above or Below the Plug.

- Pressure Energized Stem Packing

- Ball Bearing Ensures Smooth Operation and More Accurate Seat Adjustments.

- Gear operated above 6″

[google-square-ad]

Operators :

- Manual using wrench.

- Bare stem with mounting flange for actuation.

- Manual worm gear with vertical handwheels.

- Manual worm gear with horizontal handwheels.

- Manual worm gear with one vertical and one horizontal handwheel.

Patterns :

- Short Pattern

- Regular

- Regular Full Bore

- Venturi

Applicable Codes and Standards

- ASME B16.5 : Flanges connections dimensions.

- Face to Face dimensions as per manufacturer.

Materials of Construction

- Body : Cast Steel ASTM A 216 Grade WCB

- Cover : EN 10025-2 S355J2

- Plug : Cast Iron ASTM A 126 Class B