The double pipe or fin-tube exchangers are commonly used in process industry when one liquid has a greater resistance to heat flow than another or when the surface area is small. In these cases, addition of fins to the inner pipe evens out the resistance to heat flow of the two fluids.

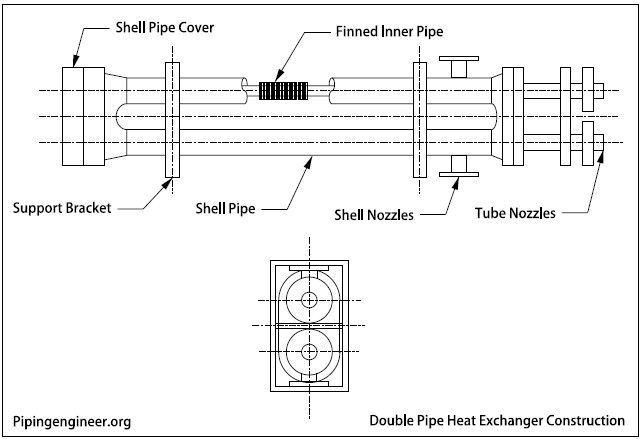

As shown below, the double pipe heat exchanger consists of a pipe within a pipe. Both pipes have a return bend at one end.

The inner pipe is fitted with fins. The outer pipe acts as shell.

The shell nozzles are mounted vertically from the outer pipe, and the tube nozzles are directly welded to the inner pipe ends.

The units are generally supported horizontally by brackets attached to a foundation or to the side of other equipment supports.