Tags: #piping_engineering #piping_welding #edge_preparation #piping_fabrication

Edge Preparation

The edges to be welded shall be prepared to meet the joint design requirements by any of the following methods recommended:

- Carbon Steel : Gas cutting, machining or grinding methods shall be used. After gas cutting, oxides shall be removed by chipping or grinding.

- Low Alloy Steels (containing up to 5% Chromium) : Gas cutting, machining or grinding methods shall be used. After gas cutting,

machining or grinding shall be carried out on the cut surface. - High alloy steel(> 5% Chromium) and stainless steels, nickel alloys: Plasma cutting, machining or grinding methods shall be used. After plasma cutting, cut surfaces shall be machined or ground smooth.

Cleaning

The ends to be welded shall be properly cleaned to remove paint, oil, grease, rust, oxides, sand, earth and other foreign matter. The ends shall be completely dry before the welding commences.

[google-square-ad]

Pipe End Beveling

Pipe end must be beveled as per applicable standard using pipe beveling machine. Dimensions of bevel must be measured correctly.

Check Pipe End Magnetism

Magnetism can be detrimental to the quality of pipe weld. After pipe end is beveled, it is essential to check any residual magnetism at pipe end. If found, pipe must be demagnetized.

[google-square-ad]

Alignment and Spacing

Components to be welded shall be aligned and spaced as per the requirements laid down in applicable code. Special care must be taken to ensure proper fitting and alignment when the welding is performed by GT AW process. Flame heating for adjustment and correction of ends is not permitted unless specifically approved by the Engineer-in-Charge.

A wire spacer of suitable diameter may be used for maintaining the weld root opening while tacking, but it must be removed after tack welding and before laying the root bead.

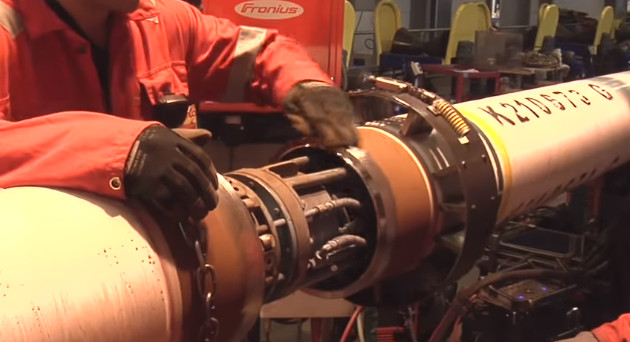

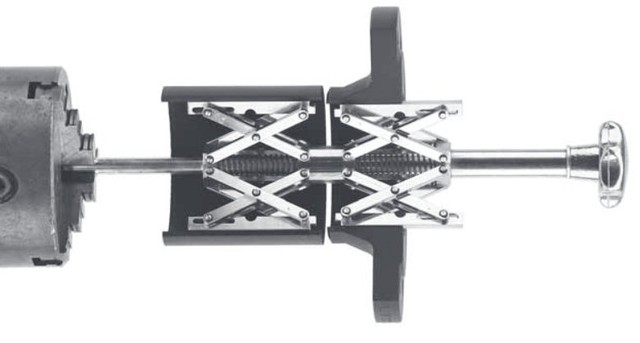

For pipes of wall thickness 5 mm and above, the ends to be welded shall be secured in position with the aid of couplers, yokes and ‘C’ clamps, to maintain perfect alignment. Yokes shall be detached after the completion of weld, without causing any surface irregularity. Any irregularity caused on the pipe surface must be suitably repaired to the satisfaction of the Engineer-in-Charge.

[google-square-ad]

Tack Welding

Tack welds, for maintaining the alignment, of pipe joints shall be made only by qualified welders using approved Welding Procedure Specification. Since the tack welds become part of the final weldment they shall be executed carefully and shall be free from defects. Defective tack welds must be removed prior to the actual welding of the joints.

- 3 tacks – for 2 1/2″ and smaller dia. pipes.

- 4 tacks – for 3″ to 12″ dia. pipes.

- 6 tacks – for 14″ and larger dia. pipes.

Welding shall commence only after approval of fit-up by the Engineer-In-Charge.