For larger size pipes and where pressure drop in elbow is not critical, miters can be used instead of standards elbows.

Here is formula to calculate required dimensions to fabricate miter from pipe.

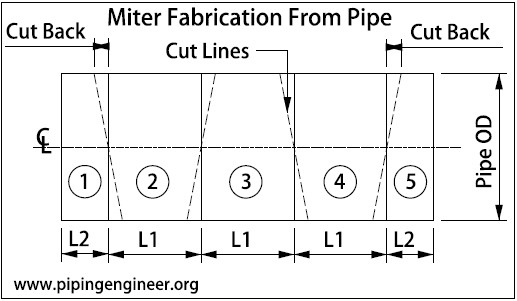

In the figure above, dotted lines are where the pipe should be cut. Each dotted cut line has a vertical reference line marked at following distances from pipe end.

- L2 : Distance of first and last reference line from pipe ends.

- L1 : Distance between reference lines.

- Cut Back : Offset distance of cut lines from reference lines at the top and bottom of pipe.

[google-square-ad]

Formulas to calculate above distances

[latexpage]

\[L1=\tan(\frac{D}{N\times2})\times{E}\times{2}\]

\[L2=\frac{L1}{2}\]

\[Cutback =\frac{ \tan(\frac{D}{N\times2})\times{POD}}{2}\]

Where :

- D : Required elbow degrees.

- N : Numer of cuts.

- E : Elbow center radius required.

- POD : Pipe Outside Diameter.

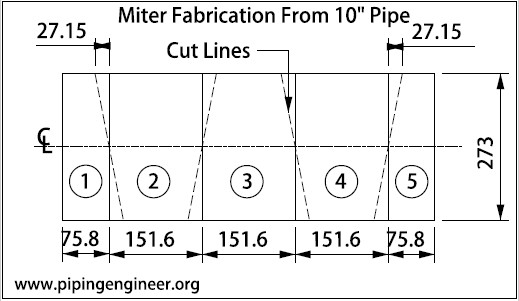

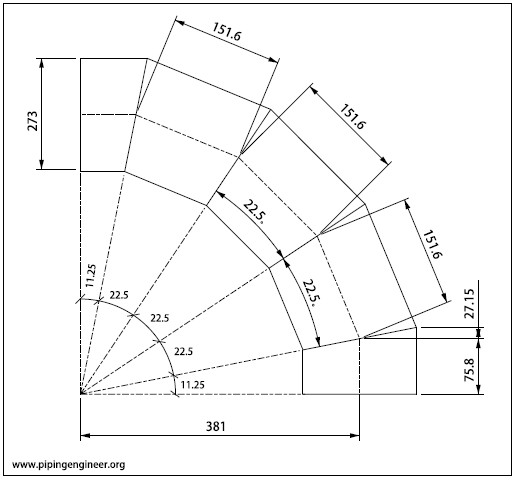

Sample Miter Calculation

Consider we want to create 90 degree elbow of 10″ size with elbow center radius same as standard elbow i.e. 381 mm.

So we have input values as :

- D = 90 mm : Required Elbow Degree

- N = 4 : Number of cuts

- E = 381 mm : Standard Elbow Radius

- POD = 273 mm : Pipe Outside Diameter

\[L1=\tan(\frac{90}{4\times2})\times{381}\times{2}\]

L1 = 151.6 mm

\[L2=\frac{151.6}{2}\]

L2 = 75.8 mm

\[Cutback =\frac{ \tan(\frac{90}{4\times2})\times{273}}{2}\]

Cutback = 27.15 mm

[google-square-ad]

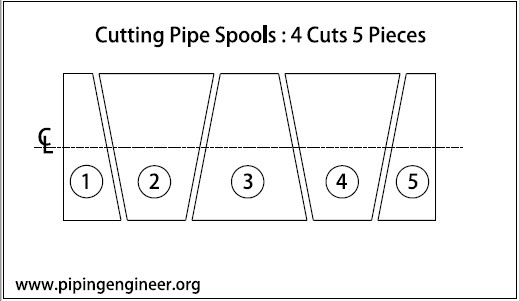

Pipe Spools

Miter Fabrication From Pipe