Insulation kits are designed to prevent galvanic corrosion between flanges of dissimilar metals, for example a carbon steel flange bolted to a stainless steel flange. A conducting liquid such as water must be present between the two flanges for galvainc corrosion to occur. On oil and dry gas duties, insulating gaskets ARE NOT required.

Because of the general unreliability of insulating gaskets, their use should be minimised to areas where only absolutely necessary and only then when agreed with by your Engineering Department.

If used, the insulation kit will consist of the following:

- insulating gasket;

- insulating sleeves to be placed around the studbolts;

- insulating washers and steel washers.

Note: The conditions that cause galvanic corrosion (two dissimilar metals brought into contact with a conducting medium) must be guarded against. Uncoated carbon steel studbolts used on stainless steel flanges in a wet environment, and carbon steel pipework screwed into brass gate valves on water duties, are two examples of “galvanic cells” which can easily be avoided.

Three types of kit are available:

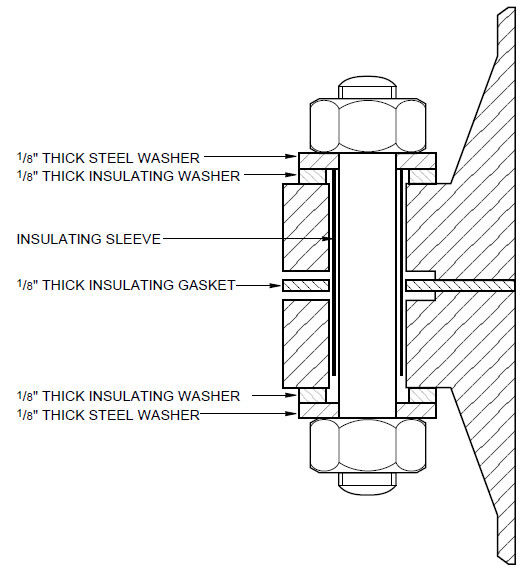

Full Face Gasket Insulating Set

This set is suitable for both flat face and raised face flanges. The gasket style has the advantage of minimising the ingress of foreign matter between the flanges and therefore reduces the risk of a conductive path between the two flanges.

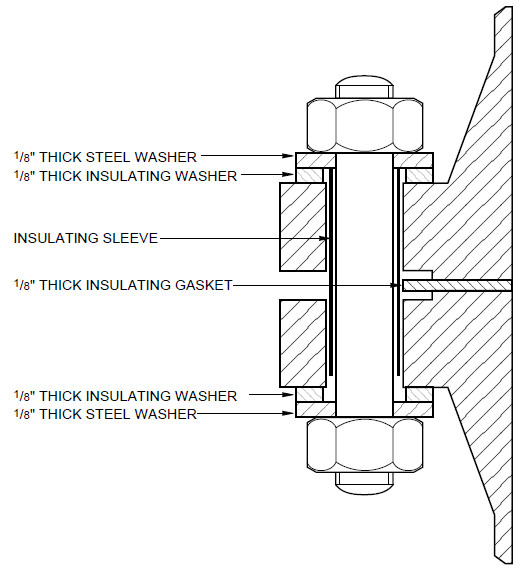

Inside Bolt Location Gasket Insulating Set

Is only suitable for raised face flanges and the gasket is located within the bolts.

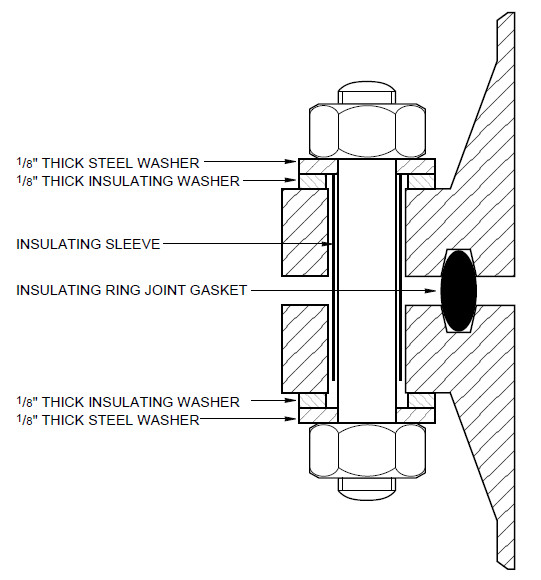

Ring Joint Gasket Insulating Set

The insulating oval RTJ will fit into a standard RTJ flange ring groove. The kits are not used on some projects as they are presently considered to be too unreliable.

Insulating Kit Identification and Specification

- Nominal Pipe Size and Pipe Schedule: Must always be specified. Insulating gaskets, unlike CAF gaskets, are an exact fit, from the OD to the ID of the flange.

- Flange Pressure Class: Always to be specified.

- Style of Insulating Kit: Full face or inside bolt location. RTJ gasket insulating sets are not used on many projects.

- Gasket Material: Usually phenolic laminate or neoprene faced phenolic laminate.

Insulating Kits – Do’s and Don’ts

Do’s

- Always use a new insulating kit which has not been removed from the manufacturer’s sealed package. Good insulation requires the insulating parts of the kit to be clean and undamaged.

- Always use a torque wrench or tensioning equipment to tension the studbolts to the manufacturer’s recommendations. This is important as insulating gaskets can easily get split or crushed if bolt tension becomes too high.

- Ensure that the flange face and the studbolts are clean.

- Also check for any conducting paths between the two mating flanges otherwise insulating gaskets will become ineffective.

- Always follow the manufacturer’s installation instructions. In case of any doubt, seek advice from your Engineering Department.

Don’ts

- Old, damanged or incluean insulating kits do not provide proper insulation. Also they may fail quite early.

- Also do not mix and match parts from different insulation kits.

- Do not use air driven impact tools when bolting up a flange as the may cause the insulating washers to crack.