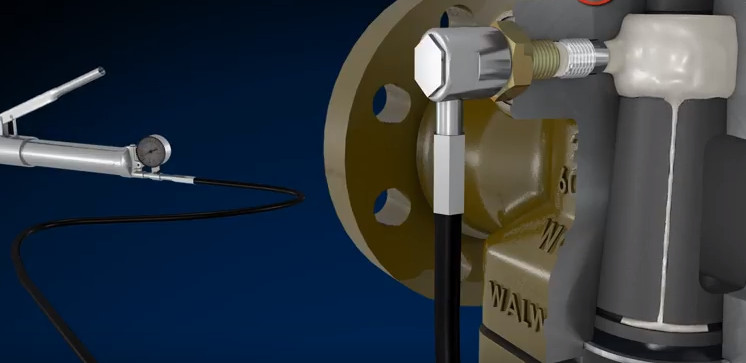

Lubricated plug valve consists of a cavity in the middle of plug along its axis. This cavity is closed at the bottom and fitted with a sealant-injection fitting at the top. The sealant is injected into the cavity, and a check valve below the injection fitting prevents the sealant from flowing in the reverse direction. The sealant oozes out from the center cavity through radial holes into lubricant grooves that extend along the length of the seating surface of the plug.

Tags : #Piping_Engineering #Piping_Valves #Plug_Valves #Lubricated_Plug_Valves

[google-square-ad]

Advantages

- Sealant helps create a renewable seal between plug and the body which prevents internal leakage.

- It also protects the seating surface against corrosion.

- It also acts as a lubricant and reduces force required to operate the valve.

- Lubricant pressure momentarily lifts the plug from the seat and makes it easy to turn.

- Also its high pressure assures no trapping of solids between valve body and plug.

Lubricated Plug Valve by DHV

Sealant/Lubricant Requirements

Sealant must be such that it should not get washed away with fluid, otherwise fluid will get contaminated. Also it should be able to withstand line temperature.

Lubricants in plug valves are actually plastic sealants. Using effective sealant with properties such as proper elasticity, resistance to solvents and chemicals and ability to form an impervious seal around each body part even under pressure is essential. The film of lubricant also protects the metal surfaces between the plug and body from corrosion.

[google-square-ad]

Availability

Lubricated plug valves are normally manufactured in sizes ranging from NPS 1⁄2 through 36 (DN 15 through 900). They can be used in applications with pressures over 2500 psi (17250 kPa).

Check out this video on youtube about lubrication procedure for plug valves by WalWorth Valves.