Piping fabrication is a critical activity on any oil and gas, petrochemicals, chemicals or any other construction projects where piping networks are required. It is necessary to ensure maximum quality of work in this activity to ensure proper functioning of piping network and minimize accidents. Check out following articles providing info about piping fabrication.

Typical piping fabrication projects involve various activities like storage and handling of piping materials, cutting, cleaning ends, welding, threading, inspection and testing, painting, insulation installation etc.

Tools and Equipments used

Various types of tools and equipments are required for piping fabrication. Here is a list of such tools used in piping fabrication.

Miter Fabrication

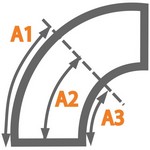

Where pressure drop is not critical, elbows are made from pipe cut at various angles. Following posts shows how to cut pipe for miter fabrication.

Cutting Elbows

Many times, elbows of non-standard angles (apart from 45 and 90 degrees) are required, which are cut form standard degree elbows. Here is page explaining how to cut them.

Pipe Branches Fabrication

Many times, pipe branches are fabricated by directly welding branch pipe to header pipe. In such cases, hole cutting profile for header pipe and cut back profile for branch pipe needs to be created.

Piping Welding

After cutting and end preparation, piping components are welded together using various welding methods.