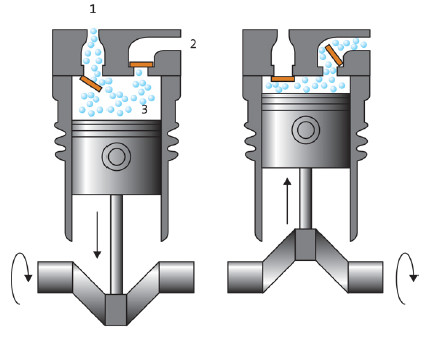

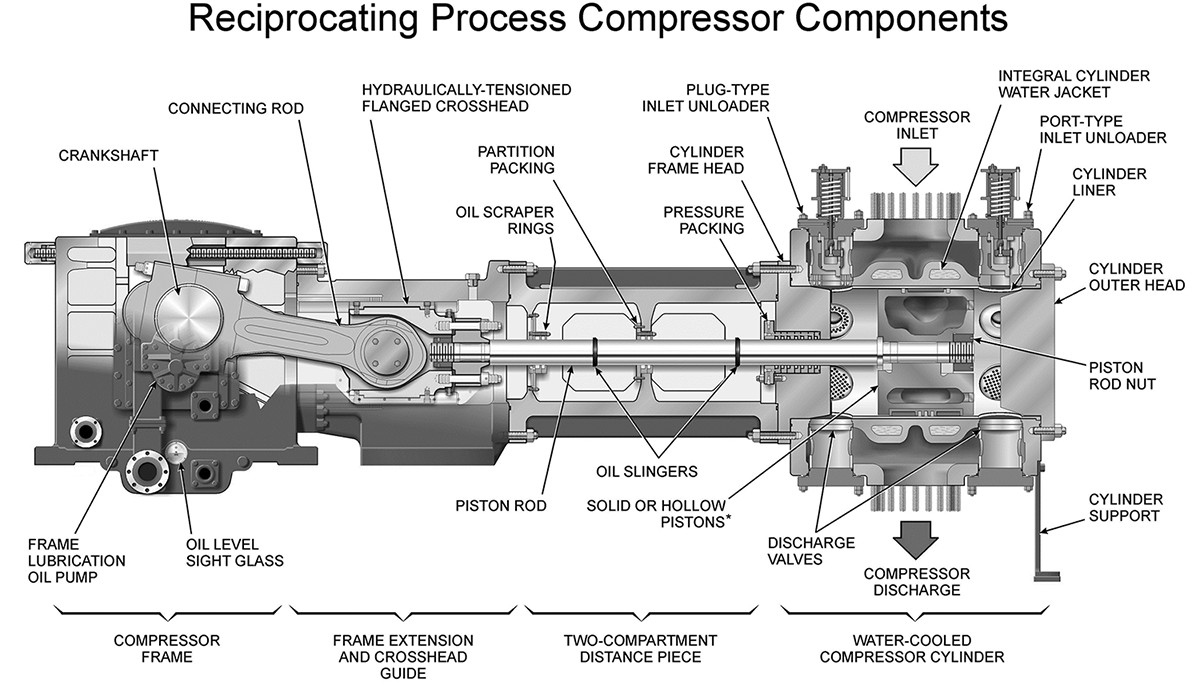

Reciprocating compressors are usually of the reciprocating piston type and are only compressors that can compress gas to extremely high pressures.

Reciprocating compressors use pistons driven by a crankshaft.

They can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines.

Small reciprocating compressors from 5 to 30 horsepower (hp) are commonly seen in automotive applications and are typically for intermittent duty.

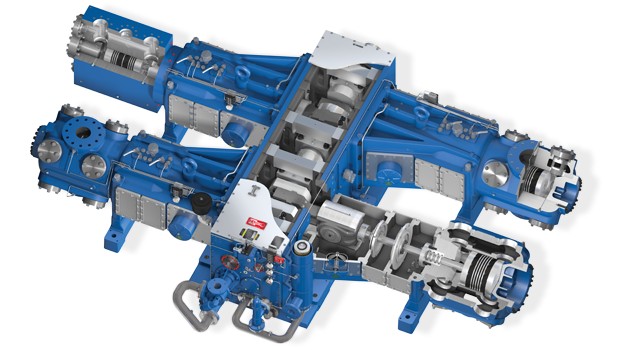

Larger reciprocating compressors well over 1,000 hp (750 kW) are commonly found in large industrial and petroleum applications.

Discharge pressures can range from low pressure to very high pressure (>18000 psi or 180 MPa).

In certain applications, such as air compression, multi-stage double-acting compressors are said to be the most efficient compressors available, and are typically larger, and more costly than comparable rotary units.

Another type of reciprocating compressor is the swash plate compressor, which uses pistons which are moved by a swash plate mounted on a shaft.

Household, home workshop, and smaller job site compressors are typically reciprocating compressors 1½ hp or less with an attached receiver tank.