Most widely used dimensional standards for Steel Pipes are ASME B36.10M and ASME B36.19M.

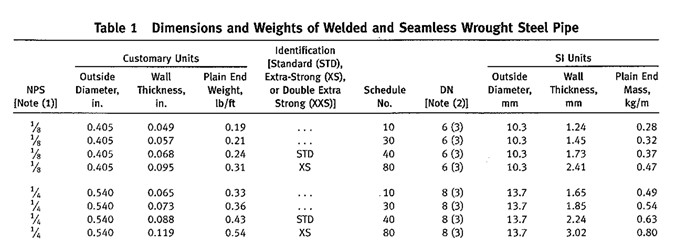

ASME B36.10M : Dimensional Standard for Carbon Steel Pipes.

- Available Size range of pipes is from 1/8″ to 80″ NPD.

- The manufacture of pipe NPS 1/8″ to NPS 12″ inclusive is based on standardized outside diameter (OD).

- The manufacture of pipe NPS 14 and larger is based on OD corresponding to nominal size.

- This standard provides formula for calculating weight of pipe in lb/foot and kg/m.

- The threads of threaded pipe should confirm to ASME B1.20.1, Pipe threads, General Purpose (Inch).

- Schedule 5 and 10 wall thickness do not permit threading as per ASME B1.20.1

- Standard and Sch.40 are identical upto 10″ inclusive. All larger sizes of Standard have 9.53mm wall thickness.

- Extra Strong and Schedule 820 are identical upto 8″. All larger sizes of XS have 12.7 mm wall thickness.

- Pipes of wall thicknesses other than those of STD, XS, XXS and Sch numbers were adopted from API Specification 5L. No schedule numbers are allotted to them.

Table 1 of this standard provides dimensions of pipes.

[google-square-ad]

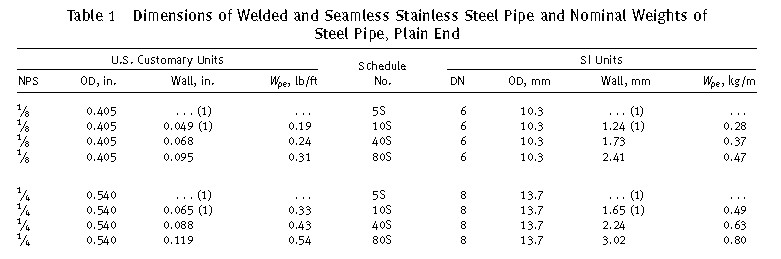

ASME B36.19M : Dimensional Standard for Stainless Steel Pipes.

- Available size range of pipes is from 1/8″ to 30″ NPD.

- Pipes 12″ and smaller have outside dia numerically larger than their corresponding sizes.

- The wall thickness for 14″ to 22″, of sch 10S, 12″ of Sch 40S and 10″,12″ of Sch 80S are not same as those of ASME B36.10M.

- Suffix S is added to differentiate thicknesses from B36.10M thicknesses.

- The manufacture of pipe NPS 1/8″ to NPS 12″ inclusive is based on standardized outside diameter (OD).

- The manufacture of pipe NPS 14 and larger is based on OD corresponding to nominal size.

- This standard provides formula for calculating weight of pipe in lb/foot and kg/m.

- The threads of threaded pipe should confirm to ASME B1.20.1, Pipe threads, General Purpose (Inch).

- Schedule 5 and 10 wall thickness do not permit threading as per ASME B1.20.1

Table 1 of this standard provides dimensions of pipes.

[google-square-ad]

Wall Thickness Calculations

The nominal weights of steel pipe are calculated values and are tabulated in Table 1 of these standards. The nominal plain end weight, in pounds per foot, is calculated using the following formula:

Pounds per foot

W = 10.69(D-t)t

Kg per Meter

W = 0.0246615(D-t)t

Where :

- D : Pipe outside diameter.

- t : Specified wall thickness.

- W : The nominal plain end mass, in pounds per foot or kilograms per meter.