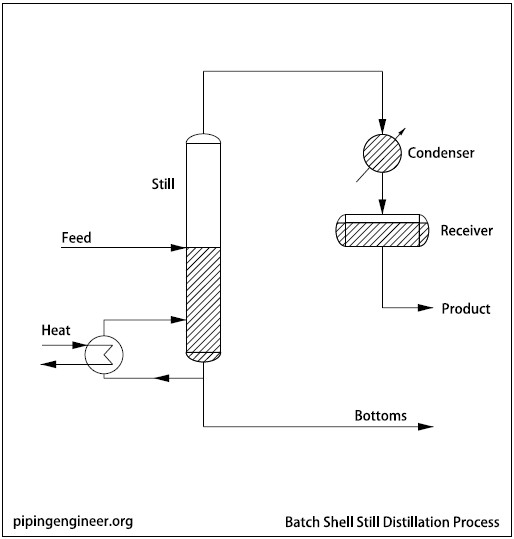

In the batch shell still process, the still is partially filled with a set feed called a batch. The feed is then heated to the temperature required to produce a specific product from the overhead vapors.

- This process is repeated each time for each product until the batch reaches a maximum temperature for the range of products specified.

- The feed remaining in the still is them pumped out, and the still is allowed to cool.

- It is them refilled, and the whole process is repeated.

Not only is this process time consuming, but the product is not always of high quality. Following figure shows the batch stilll process, which was one of the earliest used for liquid mixture separation.