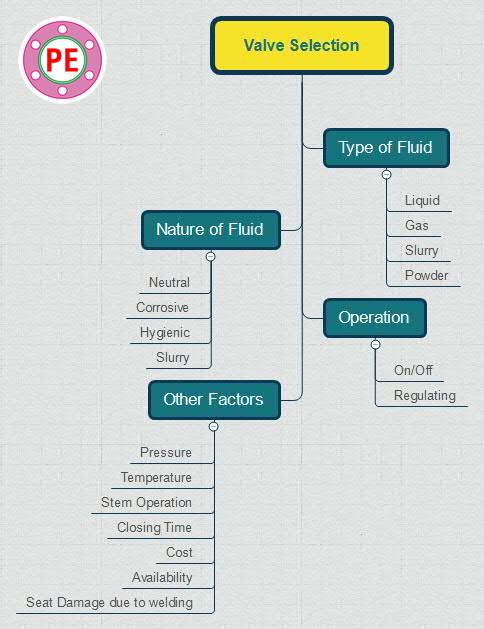

Valve selection is a important activity of a material engineer or process engineer. Key to valve selection is as follows:

Tags : #Piping_Engineering #Piping_Fittings #Piping_Valves #Valve_Selection

Valve selection is a important activity of a material engineer or process engineer. Key to valve selection is as follows:

A. First determine type of conveyed fluid : Gas, Liquid, Slurry or Powder.

B. Determine nature of fluid :

- Substantially neutral : not noticeably acid or alkanline, such as various oils, nitrogen, air, gas, drinking water etc.

- Corrosive – markedly acid, alkaline or otherwise chemically reactive.

- Hygienic – materials for food, drug, cosmetic or other industries.

- Slurry – suspension of solid particles in a liquid can have an abrasive effect on valves etc. Non-abrasive slurries such as wood-pulp slurries can choke valve mechanisms.

C. Determine required operation

- ‘On/Off” – Fully open or fully closed.

- Regulating – including close regulation (throttling)

D. Other factors affecting choice

- Pressure

- Temperature

- Stem operation method.

- Closing time required e.g. quick closing.

- Cost

- Availability of valve

- Special installation problems – such as welding valves into lines. Welding heat will sometimes distort the body and affect the sealing of small valves.