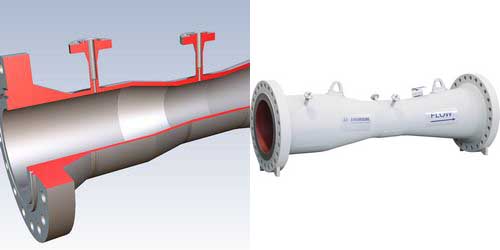

Ventury flow meter works on the principle of Ventury Effect. A reduction in fluid pressure occurs when a fluid flows through a constricted section of pipe. This happens mainly due to increased flow velocity because of reduced cross section.

Reduction in pressure is related to actual fluid velocity as well as density of the fluid. Pressure is measured at normal cross section as well as constricted cross section, to get the differential pressure. Based on this differential pressure, fluid velocity and hence volumetric flow rate can be determined.

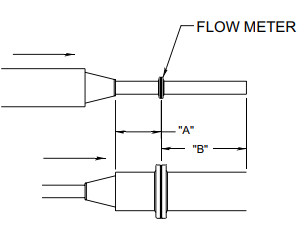

Straight Length Requirements

Terminology

Diameter (D) = nominal Pipe Size

Example:

13 Diameters of 6″ pipe = 78″

13 Diameters of 10″ pipe = 130″

Beta = (Bore I.D./Pipe I.D.)

Bore is the smallest diameter of an orifice or nozzle

Up = Upstream Diameters

Down = Downstream Diameters

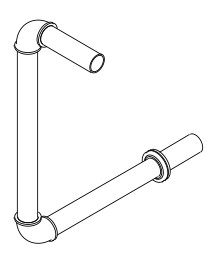

Two Elbows, > 10 Diameters, Fittings in Different Planes

When Beta is both 0.5 or 0.7 , upstream straight lenght shall be minimum 21D and downstream straight length shall be minimum 2D.

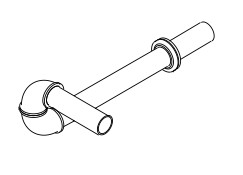

Two Elbows, < 10 Diameters, Fittings in Different Planes

When Beta is both 0.5 or 0.7 , upstream straight lenght shall be minimum 21D and downstream straight length shall be minimum 2D.

Reducer or Expander (Unless Another Upstream fitting Needs More)

If upstream has a reducer, then if Beta is 0.5, upstream straight length shall be minimum 5D and downstream shall be minimum 2D. Also in this case if Beta is 0.7, upstream straight length shall be minimum 8D and downstream shall be minimum 4D.

If upstream has an expander, then if Beta is 0.5, upstream straight length shall be minimum 2D and downstream shall be minimum 2D. Also in this case if Beta is 0.7, upstream straight length shall be minimum 4D and downstream shall be minimum 4D.

Images