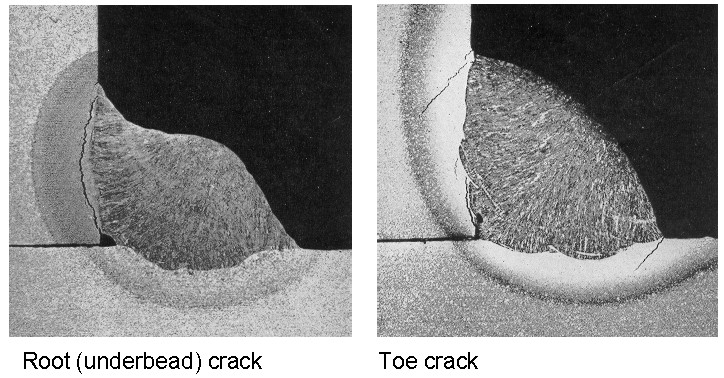

Hydrogen induced cracking occurs primarily in the grain-coarsened region of the HAZ, and is also known as cold cracking, delayed cracking or under-bead / toe cracking.

Under-bead cracking lies parallel to the fusion boundary, and its path is usually a combination of inter-granular and trans-granular cracking. The direction of the principal residual tensile stress can, for toe cracks, cause the crack path to grow progressively away from the fusion boundary towards a region of lower sensitivity to hydrogen cracking. When this happens, the crack growth rate decreases and eventually arrests.

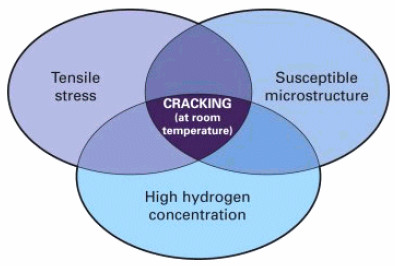

A combination of four factors is necessary to cause HAZ hydrogen cracking:

- Hydrogen level > 15 ml/100 g of weld metal deposited.

- Stress > 0.5 of the yield stress

- Temperature < 300 Degree Celcius.

- Susceptible micro-structure > 400 HV hardness.

If any one factor is not satisfied, cracking is prevented. Therefore, cracking can be avoided through control of one or more of these factors.

- Apply preheat (to slow down the cooling rate and thus avoid the formation of susceptible micro-structures).

- Maintain a specific inter-pass temperature (same effect as preheat).

- Post heat on completion of welding (to reduce the hydrogen content by allowing hydrogen to effuse from the weld area).

- Apply PWHT (to reduce residual stress and eliminate susceptible micro-structures).

- Reduce weld metal hydrogen by proper selection of welding process/ consumable (eg use TIG welding instead MMA, use basic covered electrodes instead cellulose ones).

- Use multi-run instead single-run technique (eliminate susceptible micro-structures by means of self tempering effect, reduce the hydrogen content by allowing hydrogen to effuse from the weld area).

- Use a temper bead or hot pass technique (same effect as above).

- Use austenitic or nickel filler (avoid susceptible micro-structure formation and allow hydrogen diffusion out of critical areas).

- Use dry shielding gases (reduce hydrogen content).

- Clean joint from rust (avoid hydrogen contamination from moisture present in the rust).

- Reduce residual stress.

- Blend the weld profile (reduce stress concentration at the toes of the weld).