Welding is a primary piping fabrication activity. It is critical to ensure high quality welds to ensure safe plant operation. Various methods are used to make sure the welds are of highest quality such as referring best international standards, creating approved welding qualification procedures etc.

Applicable Codes and Standards

In process industry, most widely used codes are :

- ASME Codes such as B31.1, B31.3, B31.4, B31.8 etc.

- ASME Boiler and Pressure Vessel Code.

Some countries have their own local codes applicable to certain systems such as in India, steam piping must confirm to IBR regulations.

|  | |

| All welding work, equipments for welding, heat treatment, other auxiliary functions and the welding personnel shall …Read More.. | ||

Project Welding Specification

Normally in hydrocarbon industry, carbon steel, alloy steel and stainless steel are the base materials to be welded. Project welding specification is a primary document that must be referred by welding contractor while carrying out his work. This specification includes all the requirements of welding for the particular project.

Shop Welds and Field Welds

Piping isometric drawing is marked with shop welds and field welds. Shop welds are preferred as much as possible as weld quality can be tightly controlled in shop. But maximum transportable spool size must be considered as well as any field mismatch of dimensions.

|  | |

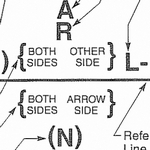

| Here is an explanation of a welding symbols as per AWS A2.4, a welding standard …Read More.. | ||

Weld MTO

Weld MTO is specified in inch-dia which is number of welds multiplied by pipe diamter.

Welding Equipments.

Welding Electrodes

Welding electrodes are used as filler materials in welding. They should match the base material to be welded, welding procedure and welding equipment.

|  | |

| Welding electrodes classification for Shielded Metal Arc Welding (SMAW) by American Welding Society (AWS) is …Read More.. | ||

|  | |

| Low hydrogen electrodes are SMAW electrodes with very low moisture content. Example of such low …Read More.. | ||

|  | |

| Project welding specification specifies various requirements for welding electrodes used in welding of piping systems. …Read More.. | ||

Shielding and Purging Gas

Shielding and purging gas is required to avoid detrimental effects of environmental oxygen on metal under welding at very high welding temperatures. Inert gases such as argon is used for such purposes. Argaon gas is required to be of 99.995 percent purity for many projects.

|  | |

| Shielding and Purging Gas Argon gas used in GTA welding for shielding purposes shall be 99.995% …Read More.. | ||

Qualification of Welders

Welders must be qualified as per applicable code e.g. B31.3

Welding Contractor’s Scope of Work

All the welding equipment like transformers, thermocouples, pyro-meters, automatic temperature recorders, heat treatment equipmets etc. is provided by welding contractor. All the weld testing equipment like radiographic equipments, radiographic films, darkroom facilities, dye-penetrant testing, magnetic particle testing, ultrasonic testing etc. are provided by the welding contractor.

Check out documents to be submitted by welding contractor.

Welding Processes

Generally used welding processes are SMAW and GTAW.

SMAW : Shielded Metal Arc Welding Process

GTAW : Gas Tungsten Arc Welding Process

Which welding process to be emplyed where is given in Project Welding Specification.

Check out these videos from youtube to have a look of these methods.

Shielded Metal Arc Welding Demo

|  | |

| Working in a safe manner, whether in the workshop or on site, is an important …Read More.. | ||

Welding Procedure

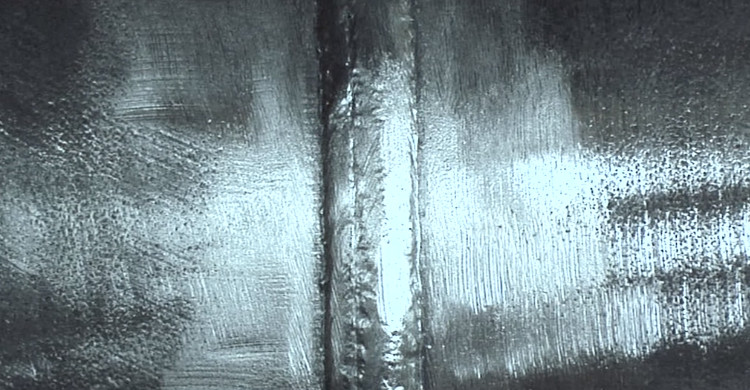

Before starting welding, it is essential to carry out edge preparation procedure for different types of base materials. It involves cleaning of edges, alignment of edges and ensuring proper spacing between them as per applicable code. Tack welding, if required is done. It is essential to protect work pieces from weather during welding. Proper welding technique is usually specified in project welding specification. Welding procedure qualification record should be submitted by Welding Contractor to the Client.

|  | |

| Tags: #piping_engineering #piping_welding #edge_preparation #piping_fabrication Edge Preparation The edges to be welded shall be prepared to meet the …Read More.. | ||

|  | |

| Root Pass Root pass shall be made with electrodes/filler wires recommended in the welding specification chart. For …Read More.. | ||

Weather conditions during welding

The parts being welded and the welding personnel should be adequately protected from rain and strong winds. In the absence of such a protection no welding shall be carried out. During field welding using GTAW process, particular care shall be exercised to prevent any air current affecting the welding process.

Preheating and Post Weld Heat Treatment

Preheating and Post Weld Heat Treatment need to be carried out as per project welding specification.

|  | |

| Preheating Heat treatment of welds is a critical activity which needs to be carried out before …Read More.. | ||

|  | |

| Post Heating In case of alloy steel materials such as Cr-Mo stels, if the post weld heat …Read More.. | ||

Cleaning of the Weld Joint.

All weld joints shall be free from adherent weld spatters slag, sward, dirt or foreign matter. This can be achieved by brushing. For stainless steels, brushes with only stainless steel bristles shall be used. Grinder with brush wheel as well as pencil grinder is used. If weld is to be coated as in case of pipelines, it must be sand blasted too.

Repairs of Welds

Repairs of welds may be done if defects are within certain limits. Defects ascertained, through the inspection methods, which are beyond acceptable limits shall be removed after the joint is completely radiographed by the process of chipping and grinding.

When the entire joint is judged unacceptable, the welding shall be completely cut and edges suitably prepared as per required alignment tolerances. The re-welded joint shall again be examined following standard practices.

No repair shall be carried out without prior permission of the owner’s inspector. Repairs and/or work of defective welds shall be done in time to avoid difficulties in meeting the construction schedules

|  | |

| Weld repairs can be divided into two specific areas: Production repairs In service repairs The reasons …Read More.. | ||